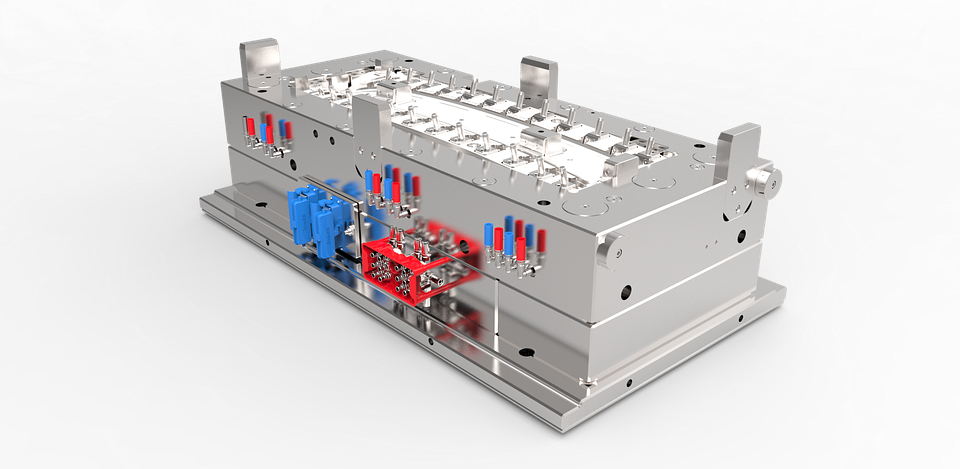

Injection Molding

Plastic injection molding is a complex procedure for fabricating plastic parts and products. It is the most versatile molding method. The machines used in this technique vary depending on material size and tonnage.

Plastic injection molding uses many types of plastic resins and additives, allowing flexibility for manufacturers.

Many industries have adopted plastic injection molding because they are able to customize their products based on the client’s needs. Manufacturers from different industries embrace the injection molding service to create high-quality products of various colors, designs and sizes. There are many industries that use plastic injection molding, including:

Pharmaceutical

The pharmaceutical industries rely on plastic injection molding to make various products like eyedroppers and syringes. This sector needs products that meet high standards like sterilization, quality and uniformity, making plastic injection molding suitable. The pharmaceutical industry also requires similar design tools to avoid miscalculations, like when manufacturing tablets or liquid. Plastic injection molding is perfect for designing such products.

Medical Industry

Healthcare professionals need many medical devices to give the best care to patients. The medical industry uses plastic injection molding to make diagnostic test kits, surgical prep, materials, stethoscope kits, device packaging and medical research instruments. Plastic injection molding manufactures high-quality devices that meet the required standards, making it ideal for use by medical companies. Plastic resins are temperature and corrosion-resistant, making them fit for the healthcare industry.

Telecommunications

The telecommunications industry uses fiber optics to transmit data and information worldwide. These cables require certain plastic adapters and parts to work appropriately, making injection molding essential to the telecommunication industry. Injection molding can design plastic adaptors, frames and casings. These products hold together electrical components and protect them from corrosive substances, increasing their effectiveness and lifespan.

Food and beverage

Plastic injection molding plays a significant role in food and beverage companies. All materials that process and store food must meet Food and Drug Administration guidelines. Plastic injection molding makes products that meet these standards, such as BPA-free and non-toxic plastics, highly benefiting the food and beverage industry. Food and beverage companies rely on injection mold to manufacture processing equipment, conveyor systems components, packaging containers and beverage over caps.

Consumer products

Most of the products you purchase or use daily at home are plastic. Injection molding is reliable for consumer products because it manufactures identical products that are durable, easy to clean, and child-safe. Some companies use plastic injection molding to craft household products, electronic tools, and automotive parts. Injection molding creates products with specialized textures, shapes and designs, making them attractive to consumers.

Transportation

Plastic injection molding is crucial in the transportation industry. It manufactures many parts and products for transport companies, like aspirators, knobs, handles, brake pads and body panels. Plastic injection molding manufacturers team up with the automotive industry to create products that comply with transport regulations. Processes such as prototyping can help test designs to ensure the injection molding products meet the required standards.

Building and construction

The building and construction industry uses plastic injection molding to craft products for their everyday work. Since building and construction companies need durable, stable, mass, and cost-effective productions, injection molding is reliable for such products with these qualities. Injection molding also customizes products for a particular application, benefiting many construction companies. Many construction industries use plastic injection molded hand tools and accessories.

Packaging

Packaging materials like lids, jars, and bottles are made through plastic injection molding. Manufacturers prefer injection molding because it produces various plastic resins and additives. You can get many packaging products with various shapes, colors, designs and shapes. Plastic resins have different formulations that can be heat, chemical, UV light, or impact resistant for particular packaging. Plastic injection molding can produce any desired appearance for packaging industries.

Shoe industry

Plastic injection molding is significant in the shoe industry due to its effectiveness. Most shoe companies use injection molding to make shoe soles. Plastic resins enable manufacturers to create molded soles that enhance comfort and weight support. Shoe manufacturers can also design shoes with unique designs, specialized textures and combinations of colors. Plastic injection molding is also cost-effective and offers mass production, essential elements for shoemaking.

Many industries are embracing plastic injection molding due to its mass production, cost-effectiveness, precision and ability to create complex parts. Manufacturers can meet their customer’s desires through different designs and sizes.