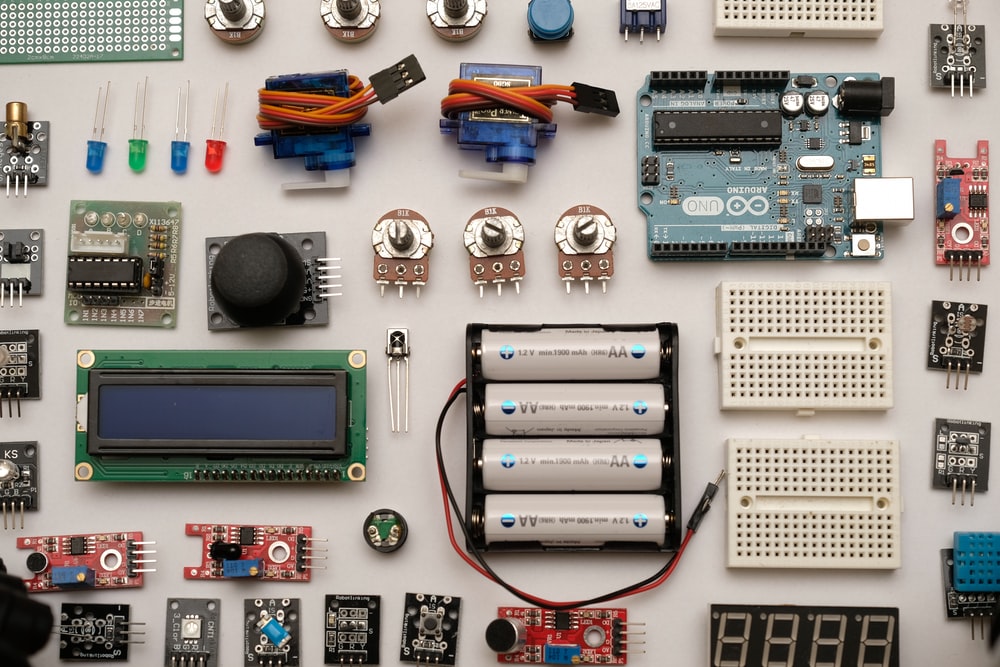

Battery

From over-the-air charging to super-fast 30-second re-charging, we’ve gathered all the top battery discoveries that could be with us soon. Also, read about electrical design courses online here.

Structured batteries may pave the way for ultra-light electric vehicles.

For a long time, researchers at the Chalmers University of Technology have been determining the use of the battery as a structural component and a source of power. The benefit is that a product’s structural components can be reduced because the battery has the strength to do such tasks.

The latest battery, which uses carbon fiber as the negative electrode and lithium iron phosphate as the positive electrode, has a stiffness of 25GPa. Yet, there is still room for improvement in energy capacity.

Carbon nanotube electrode with vertical alignment

NAWA Technologies has made and patented an Ultra-Fast Carbon Electrode, which the company claims will revolutionize the battery industry. It keeps a vertically aligned carbon nanotube (VACNT) plan, which NAWA claims may increase battery power by tenfold, energy storage by threefold, and battery lifespan by fivefold. According to the business, electric vehicles will be the biggest beneficiaries, as they will reduce the carbon footprint and expense of battery production while improving abilities. According to NAWA, a 1000km range may become the standard, with charging durations of only 5 minutes to reach 80%. As early as 2023, the technology might be in use.

A lithium-ion battery that is free of cobalt.

University of Texas researchers have developed a lithium-ion battery without cobalt as a cathode. Instead, it shifted to a nickel-based alloy with a high nickel content (89%) and manganese and aluminium as the other elements. “Cobalt is a less abundant and most expensive component in battery cathodes,” said Arumugam Manthiram, director of the Texas Materials Institute and professor at the Walker Department of Mechanical Engineering. “And we are executing every possible thing we can to get rid of it.”

SVOLT introduces cobalt-free batteries for electric vehicles.

While the benefits of electric vehicles in terms of lowering emissions are universally acknowledged, there is still debate about batteries, notably the use of metals like cobalt. SVOLT, made in Changzhou, China, has told the production of cobalt-free batteries for the electric vehicle industry. Aside from lowering rare earth metals, the company claims that they have a higher energy density, which might lead to electric car ranges of up to 800 kilometers (500 miles) and increased battery life and safety.

A step closer to lithium-ion batteries using a silicon anode

Researchers at the University of Eastern Finland got a way to make a hybrid anode utilizing mesoporous silicon microparticles and carbon nanotubes to solve the problem of unstable silicon in lithium-ion batteries. The ultimate goal is to employ silicon instead of graphite as the anode in batteries, which has ten times the capacity. The battery’s performance is improved by using this hybrid material, and the silicon is manufactured sustainably from barley husk ash.

Current batteries can be pushed past their recommended limits without hurting performance or overheating, according to scientists.